Product features

-

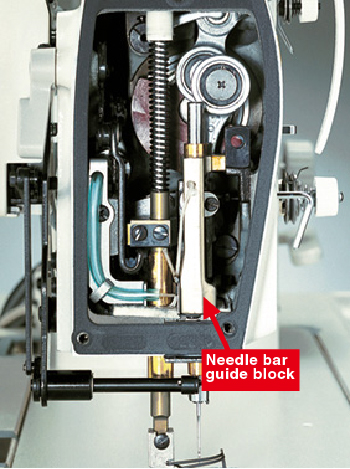

The machine is installed with a highly reliable needle feed mechanism

- Thanks to the needle-feed mechanism which offers excellent efficiency of feed, the machine ensures accurate stitch pitches (stitch length) as well as preventing slippage of the upper cloth.

The bottom feed's locus has been improved to match the needle feed motion, thus the machine produces beautiful seams without stitch gathering, even when it is used for sewing slippery and difficult-to-feed material or for handling a difficult process. - The needle feed mechanism is a so-called "dry type", which does not require oiling. With this mechanism, a highly reliable machine structure, free from oil leakage troubles, has been achieved.

The frame, which requires only a minute quantity of lubricating oil, is structured to eliminate oil leakage. - The machine can be easily changed over from a needle feed mechanism to a bottom feed mechanism easily, through a simple adjustment and gauge replacement. It is a useful feature for those users who also want to use the machine simply as a regular bottom feed type machine in accordance with applications and processes.

- Thanks to the needle-feed mechanism which offers excellent efficiency of feed, the machine ensures accurate stitch pitches (stitch length) as well as preventing slippage of the upper cloth.

-

The machine no longer uses an oil pan

With this oil pan-less structure, the machine helps create a clean work environment- The machine has been configured to eliminate the oil pan, and supplies a minute quantity of lubricating oil to the hook and needle bar, thereby contributing to the reation of a clean work environment.

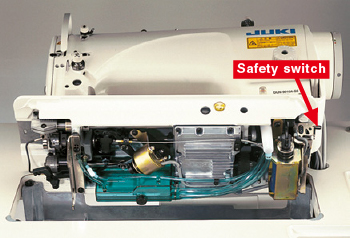

- The machine saves you the time and trouble of removing the knee-lifter and cover. This means that the machine head can be tilted for cleaning and maintenance without the inconvenience of removing the knee-lifter and cover.

- Even if you tilt the machine head while the power is still ON, the safety switch will disable the machine. This means the machine won't start running when the head is tilted even if you press the foot pedal.

-

The machine is provided with various easy-to-operate functions for increased operability

-

The new model control box, which energy-saving mode is provided (SC-920A)

The new model control box SC-920A, which consists of an energy-saving mode, has been developed. This control box is the first one which provides an energy-saving mode for the sewing machine. The power consumption during standby, when the motor is at rest, is reduced by approximately 20%.

-

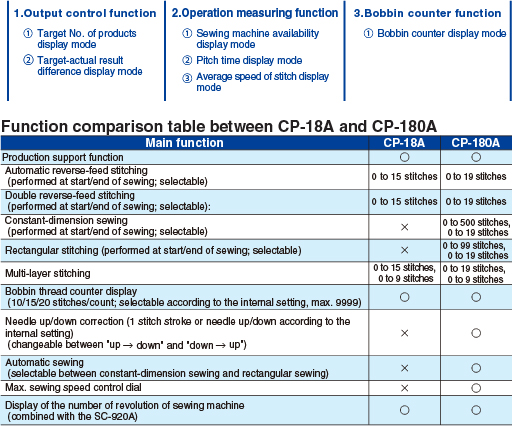

The operation panel can be selected according to the process (CP-18A,CP-180A)

Two different operation panels, the CP-18A and CP-180A are applicable to the DLN-9010A. Both operation panels are provided with the production support function.

The production support function actually consists of three different functions (six different modes)